John Deere LT 180 won't start.....

tracey_b

13 years ago

Related Stories

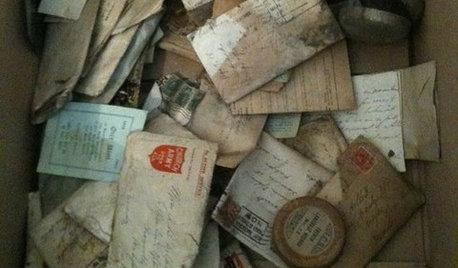

REMODELING GUIDESYou Won't Believe What These Homeowners Found in Their Walls

From the banal to the downright bizarre, these uncovered artifacts may get you wondering what may be hidden in your own home

Full Story

MOST POPULARHow to Start a Cool-Season Vegetable Garden

Late summer and late winter are good times to plan and plant cool-season crops like salad greens, spinach, beets, carrots and peas

Full Story

CONTRACTOR TIPS10 Things to Discuss With Your Contractor Before Work Starts

Have a meeting a week before hammers and shovels fly to make sure everyone’s on the same page

Full Story

HOUZZ TOURSMy Houzz: A Family Makes a Fresh Start in a Remodeled Beach House

With neutral hues and ocean views, this Malibu home offers a stunning backdrop for gatherings of family and friends

Full Story

GARDENING GUIDESOh, Deer! 10 Native Flowers That Stand Up to the Herds

Keeping a garden amid hungry deer can be hard, but these plants should fare well

Full Story

MOST POPULARGarage Cleaning Tips for the Overwhelmed

Don’t let this catch-all space get the better of you. These baby steps can get you started

Full Story

GARDENING GUIDES6 Unsung Bulbs for Fall Planting

Don't hang up your spade after summer — plant these unusual bulbs in fall for a spectacular spring show

Full Story

KITCHEN DESIGN15 Farmhouse Kitchens That Made Us Swoon This Month

Raw wood, natural light, shiplap siding — we just couldn’t get enough of these farmhouse-style kitchens uploaded to Houzz in January

Full Story

HEALTHY HOMEWhat to Know About Controlling Dust During Remodeling

You can't eliminate dust during construction, but there are ways to contain and remove as much of it as possible

Full Story

BUDGET DECORATING8 Cost-Effective Ways to Get a High-End Look

Don’t discount that expensive material yet. By using a small amount in a strategic way, you can get a luxurious look without the expense

Full StorySponsored

mownie

mownie

Related Professionals

Richmond Heights Landscape Architects & Landscape Designers · Summit Landscape Architects & Landscape Designers · Brandon Landscape Contractors · Farmington Landscape Contractors · Gurnee Landscape Contractors · Kaneohe Landscape Contractors · Mission Landscape Contractors · St. Louis Landscape Contractors · Suisun City Landscape Contractors · Castro Valley Window Contractors · 45056 Window Contractors · Baker Window Contractors · Cypress Window Contractors · Santa Cruz Window Contractors · Security-Widefield Window Contractorstracey_bOriginal Author

tracey_bOriginal Author

mownie

tracey_bOriginal Author

rcmoser

tracey_bOriginal Author

mownie

rcmoser

tomplum

tracey_bOriginal Author

tracey_bOriginal Author

leodz