Valve lash adjusting

bgrabon

16 years ago

Related Stories

BATHROOM DESIGN12 Things to Consider for Your Bathroom Remodel

Maybe a tub doesn’t float your boat, but having no threshold is a no-brainer. These points to ponder will help you plan

Full Story

BATHROOM DESIGNConvert Your Tub Space to a Shower — the Fixtures-Shopping Phase

Step 2 in swapping your tub for a sleek new shower: Determine your mechanical needs and buy quality fixtures

Full Story

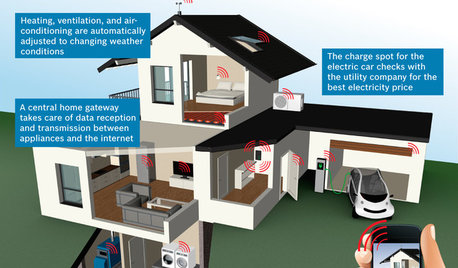

THE HARDWORKING HOMECES 2015: Inching Toward a Smarter Home

Companies are betting big on connected devices in 2015. Here’s a look at what’s to come

Full Story

HOUSEKEEPING5 Steps to Improve Your Heating System Now

Increase your heater's efficiency and safety for lower energy bills and greater peace of mind this winter

Full Story

DISASTER PREP & RECOVERYRemodeling After Water Damage: Tips From a Homeowner Who Did It

Learn the crucial steps and coping mechanisms that can help when flooding strikes your home

Full Story

BATHROOM DESIGNHow to Match Tile Heights for a Perfect Installation

Irregular tile heights can mar the look of your bathroom. Here's how to counter the differences

Full Story

UNIVERSAL DESIGN11 Ways to Age-Proof Your Bathroom

Learn how to create a safe and accessible bathroom without sacrificing style

Full Story

HOUSEKEEPINGWhat's That Sound? 9 Home Noises and How to Fix Them

Bumps and thumps might be driving you crazy, but they also might mean big trouble. We give you the lowdown and which pro to call for help

Full Story

BATHROOM DESIGNHow to Choose the Right Bathroom Sink

Learn the differences among eight styles of bathroom sinks, and find the perfect one for your space

Full Story

BATHROOM DESIGN10 Amenities to Make Your Bathroom Extraordinary

Go beyond the basics for a luxury bathroom experience, with extra-special options starting at only $25

Full StorySponsored

tmajor

fisher40037

Related Professionals

Edmond Landscape Architects & Landscape Designers · Beavercreek Landscape Architects & Landscape Designers · Sand Springs Landscape Architects & Landscape Designers · Elgin Landscape Contractors · Stoughton Landscape Contractors · Americus Landscape Contractors · Andover Landscape Contractors · Golden Gate Landscape Contractors · Huntley Landscape Contractors · Milford Mill Landscape Contractors · Richmond Landscape Contractors · Santa Ana Landscape Contractors · Wheat Ridge Landscape Contractors · Suisun City Landscape Contractors · Farragut Window Contractorsrcmoser

bgrabonOriginal Author

jsharpscs

mikie_gw

rcmoser

bgrabonOriginal Author

tmajor

bill_kapaun

bill_kapaun

engine_tech

bgrabonOriginal Author