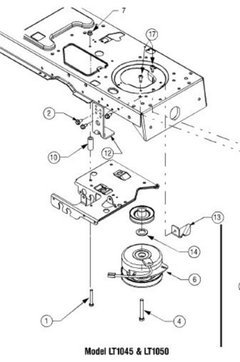

LT1045 PTO replacement

JimGilliland

11 years ago

Featured Answer

Sort by:Oldest

Comments (40)

bill_kapaun

11 years agorcbe

11 years agoRelated Professionals

Glendora Landscape Architects & Landscape Designers · Jennings Landscape Architects & Landscape Designers · Woodinville Landscape Architects & Landscape Designers · Aberdeen Landscape Contractors · Ashburn Landscape Contractors · Eureka Landscape Contractors · Harrisburg Landscape Contractors · Hollywood Landscape Contractors · San Pedro Landscape Contractors · Golden Valley Landscape Contractors · Ferguson Landscape Contractors · DeLand Window Contractors · Hammond Window Contractors · Snoqualmie Window Contractors · Trinity Window ContractorsUser

11 years agoJimGilliland

11 years agoJimGilliland

11 years agoUser

11 years agoJimGilliland

11 years agorcbe

11 years agoUser

11 years agorcbe

11 years agoUser

11 years agorcbe

11 years agoUser

11 years agoJimGilliland

11 years agoUser

11 years agoJimGilliland

11 years agoUser

11 years agoJimGilliland

11 years agoUser

11 years agoJimGilliland

11 years agoUser

11 years agorcbe

11 years agoUser

11 years agoKarrie Ann Stewart

8 years agoUser

8 years agoKarrie Ann Stewart

8 years agotomplum

8 years agoKarrie Ann Stewart

8 years agoUser

8 years agolast modified: 8 years agoKarrie Ann Stewart

8 years agoKarrie Ann Stewart

8 years agowheely_boy

8 years agoUser

8 years agolast modified: 8 years agorexlex

8 years agotomplum

8 years agoLee McLaughlin

7 years agoBrian James

5 years agoJoe Sison

last yearHU-954500340

9 days ago

Related Stories

FURNITUREOld Furniture: Clean, Reupholster or Replace It?

A veteran upholstery cleaner weighs in on the options for found, inherited and thrift store furniture

Full Story

WINDOWSContractor Tips: How to Choose and Install Windows

5 factors to consider when picking and placing windows throughout your home

Full Story

REMODELING GUIDESWhich Window for Your World?

The view and fresh air from your windows make a huge impact on the experience of being in your house

Full Story

WINDOW TREATMENTSEasy Green: 9 Low-Cost Ways to Insulate Windows and Doors

Block drafts to boost both warmth and energy savings with these inexpensive but effective insulating strategies

Full Story

HOME OFFICESPaperless Home Offices Show Reams of Style

If pesky piles of paper are ruining your interior design — not to mention a forest or two — it may be time to take the paperless plunge

Full Story

GARDENING GUIDESDo You Have This Invasive Plant in Your Yard?

Garlic mustard is spreading across the U.S. Here’s how to spot it and what to do

Full Story

CURB APPEALEntry Recipe: New Focal Point for a 1970s Ranch House

A covered terrace draws visitors to the front door and creates a modern, interesting approach in a Baltimore-area home

Full Story

SELLING YOUR HOUSE10 Tricks to Help Your Bathroom Sell Your House

As with the kitchen, the bathroom is always a high priority for home buyers. Here’s how to showcase your bathroom so it looks its best

Full Story

MATERIALSWhat to Ask Before Choosing a Hardwood Floor

We give you the details on cost, installation, wood varieties and more to help you pick the right hardwood flooring

Full Story

DECORATING GUIDESHow to Choose an Awesome Area Rug No Matter What Your Space

High use, a low door, kids and pets running amok — whatever your area endures, this insight will help you find the right rug for it

Full Story

mownie