Tractor Blades will not engage

Preacherman1

10 years ago

Related Stories

FARM YOUR YARD14 Crazy Places to Grow Edibles

Some Houzzers may lack ground for gardening, but they’re never short on imagination

Full Story

FARMHOUSESHouzz Tour: A Farmhouse in the Dell

Modern style and a barn look mix in a most unusual Sonoma County home

Full Story

LIFEFrom the Wild, Home: Elements of a Landscape of Experience

See how simplicity, mystery and lessons from nature can help you create a rich garden experience at home

Full Story

HOUZZ TOURSHouzz Tour: Modern Treetop Living in Sydney

Encouraging connections and calm, this Australian family home among the trees is all about subtlety

Full Story

LANDSCAPE DESIGNGet Along With Less Lawn — Ideas to Save Water and Effort

Ditch the mower and lower your water bill while creating a feast for the eyes with diverse plantings and gathering places

Full Story

COMMUNITY15 Ways to Make Your Neighborhood Better

Does your community lack ... well, a sense of community? Here's how to strengthen that neighborly spirit

Full Story

GREAT HOME PROJECTSHow to Give Your Driveway and Front Walk More Curb Appeal

Prevent injuries and tire damage while making a great first impression by replacing or repairing front paths

Full Story

PETS6 Ways to Help Your Dog and Landscape Play Nicely Together

Keep your prized plantings intact and your dog happy too, with this wisdom from an expert gardener and dog guardian

Full Story

KITCHEN STORAGEKnife Shopping and Storage: Advice From a Kitchen Pro

Get your kitchen holiday ready by choosing the right knives and storing them safely and efficiently

Full Story

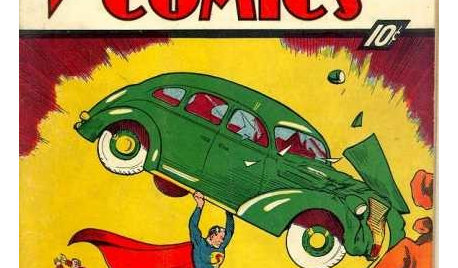

REMODELING GUIDESOne Guy Found a $175,000 Comic in His Wall. What Has Your Home Hidden?

Have you found a treasure, large or small, when remodeling your house? We want to see it!

Full Story

mownie

Preacherman1Original Author

Related Professionals

Maple Valley Landscape Architects & Landscape Designers · New Mexico Landscape Architects & Landscape Designers · Norton Shores Landscape Architects & Landscape Designers · Oconomowoc Landscape Architects & Landscape Designers · Surprise Landscape Contractors · Cincinnati Landscape Contractors · Ellicott City Landscape Contractors · Goodlettsville Landscape Contractors · Lemont Landscape Contractors · Methuen Landscape Contractors · Palos Verdes Estates Landscape Contractors · Shirley Landscape Contractors · Fort Myers Window Contractors · Brooklyn Window Contractors · Glendale Heights Window Contractorsmownie

bill_kapaun

Preacherman1Original Author

mownie

Preacherman1Original Author

mownie

tomplum

Preacherman1Original Author