JD X304 cranks but won't turn over.

ridonkulus

13 years ago

Related Stories

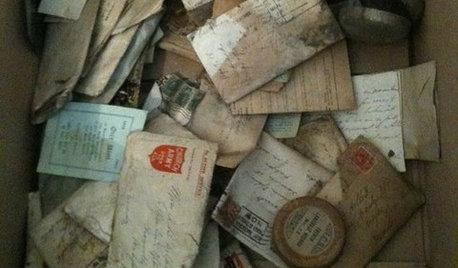

REMODELING GUIDESYou Won't Believe What These Homeowners Found in Their Walls

From the banal to the downright bizarre, these uncovered artifacts may get you wondering what may be hidden in your own home

Full Story

HOME TECH3 Kitchen Contraptions You Won’t Believe

Pizza hot from the printer, anyone? These cooking gadgets harness imagination and high tech — and have price tags to match

Full Story

KIDS’ SPACES7 Kids’ Bedroom Decor Ideas That Won’t Break the Bank

Take an economical approach to decorating your child’s room with these DIY ideas

Full Story

LIFETurn Off the Video Games and Turn On Your Kid's Creativity

Going nuts planning summer activities? Kids overdosing on screen time? It may be time to foster more self-directed play

Full Story

GREAT HOME PROJECTSTurn That Spare Room Into a Walk-in Closet

New project for a new year: Get the closet you’ve always wanted, starting with all the info here

Full Story

HOME TECHComing Soon: Turn Your Kitchen Counter Into a Touch Screen

Discover how touch projection technology might turn your tables and countertops into iPad-like devices — and sooner than you think

Full Story

HOUZZ TOURSHouzz Tour: Watch a Sliding Wall Turn a Living Space Into 5 Rooms

A clever custom storage piece transforms this New York City microstudio into multiple living spaces

Full Story

DIY PROJECTSTurn a Shipping Pallet Into a Stylish Ottoman

Get the step-by-step instructions for upholstering your own mod living room centerpiece

Full Story

SHOWERSTurn Your Shower Niche Into a Design Star

Clear glass surrounds have raised the design bar for details such as shampoo and soap shelves. Here are 4 standouts

Full Story

LIGHTINGGet Turned On to a Lighting Plan

Coordinate your layers of lighting to help each one of your rooms look its best and work well for you

Full StorySponsored

mownie

User

Related Professionals

Franconia Landscape Architects & Landscape Designers · Garden City Landscape Architects & Landscape Designers · El Sobrante Landscape Contractors · Fort Worth Landscape Contractors · Harrisburg Landscape Contractors · McLean Landscape Contractors · Middletown Landscape Contractors · Palatine Landscape Contractors · Tustin Landscape Contractors · Washington Landscape Contractors · Arlington Window Contractors · Decatur Window Contractors · Greenwich Window Contractors · Winnetka Window Contractors · Discovery Bay Window ContractorsridonkulusOriginal Author

User

ridonkulusOriginal Author

ridonkulusOriginal Author

tomplum

mownie

ridonkulusOriginal Author

ridonkulusOriginal Author

tomplum

mownie

ridonkulusOriginal Author

ridonkulusOriginal Author

ridonkulusOriginal Author

mownie

ridonkulusOriginal Author

tomplum

mownie

ridonkulusOriginal Author