craftsman ys4500 54 in mower wont start

kemon66

10 years ago

Related Stories

REMODELING GUIDESHouzz Tour: Turning a ’50s Ranch Into a Craftsman Bungalow

With a new second story and remodeled rooms, this Maryland home has plenty of space for family and friends

Full Story

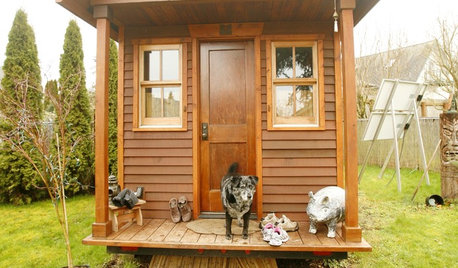

SMALL SPACESLife Lessons From 10 Years of Living in 84 Square Feet

Dee Williams was looking for a richer life. She found it by moving into a very tiny house

Full Story

KITCHEN DESIGNA Cook’s 6 Tips for Buying Kitchen Appliances

An avid home chef answers tricky questions about choosing the right oven, stovetop, vent hood and more

Full Story

MOST POPULARHow to Add a Backyard Shed for Storage or Living

Need a home office, a playspace or extra room for your stuff? Learn about off-the-shelf, prefab and custom sheds

Full Story

LANDSCAPE DESIGN7 Low-Maintenance Lawn Alternatives

Turf isn't the only ground cover in town. Get a lush no-grass lawn with clover, moss and other easy-care plants

Full Story

FURNITUREDecorating 101: How to Shop for Furniture

Learn what furniture to get rid of, what to look for when buying, and how to avoid mistakes

Full Story

LIGHTINGGet Turned On to a Lighting Plan

Coordinate your layers of lighting to help each one of your rooms look its best and work well for you

Full Story

CURB APPEAL77 Front Doors to Welcome You Home

Crossing the threshold is an event with these doors in a gamut of styles

Full Story

ARCHITECTUREHouse-Hunting Help: If You Could Pick Your Home Style ...

Love an open layout? Steer clear of Victorians. Hate stairs? Sidle up to a ranch. Whatever home you're looking for, this guide can help

Full Story

REMODELING GUIDESWhere to Splurge, Where to Save in Your Remodel

Learn how to balance your budget and set priorities to get the home features you want with the least compromise

Full StorySponsored

rcbe

bill_kapaun

Related Professionals

Arlington Landscape Architects & Landscape Designers · Stamford Landscape Contractors · Dallas Landscape Contractors · Eagle Landscape Contractors · Elkridge Landscape Contractors · Ellicott City Landscape Contractors · Hickory Hills Landscape Contractors · Hollywood Landscape Contractors · La Vista Landscape Contractors · Painesville Landscape Contractors · Porterville Landscape Contractors · Vacaville Landscape Contractors · Markham Landscape Contractors · Town 'n' Country Window Contractors · Scotts Valley Window Contractorskemon66Original Author

bill_kapaun

kemon66Original Author

rcbe

bill_kapaun

mownie

kemon66Original Author

kemon66Original Author

rcbe