JD l120 moaning noise

mc32095

11 years ago

Related Stories

THE HARDWORKING HOME8 Laundry Room Ideas to Watch For This Year

The Hardworking Home: A look at the most popular laundry photos in 2014 hints that dog beds, drying racks and stackable units will be key

Full Story

MODERN HOMESHouzz Tour: Fieldstone Divides and Connects a Wisconsin Home

Modern architecture looks right at home on its site, thanks in part to a bold north-south wall of local stone

Full Story

HOUSEKEEPINGChoose Your Own Spring Cleaning Plan

Instead of trying to do it all, pick one of these six cleaning approaches that’s right for you now

Full Story

CONTEMPORARY HOMESHouzz Tour: From Anonymous to Outstanding in Georgia

With a striking front porch and a dynamic wood ribbon inside, this Decatur home moves ahead of the curve

Full Story

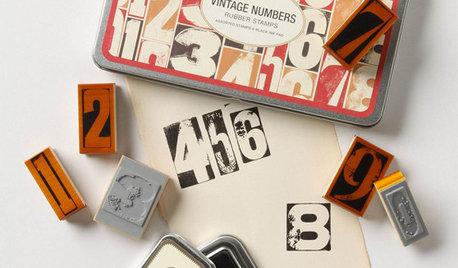

50 Great Gifts Under $50

Our favorite budget-minded holiday gifts for the design lovers on your list

Full Story

tomplum

rcbe

Related Professionals

Carson Landscape Architects & Landscape Designers · Lake Oswego Landscape Architects & Landscape Designers · Finneytown Landscape Architects & Landscape Designers · Aurora Landscape Contractors · Pottstown Landscape Contractors · Azalea Park Landscape Contractors · Byram Landscape Contractors · Glendale Heights Landscape Contractors · Kahului Landscape Contractors · New Braunfels Landscape Contractors · Ocoee Landscape Contractors · Wanaque Landscape Contractors · Gardere Window Contractors · Holly Hill Window Contractors · Sunrise Window Contractorsmc32095Original Author

rcbe

mownie

tomplum

mc32095Original Author

mownie

rustyj14

mc32095Original Author

mownie

krnuttle

mownie