Indexing valves, toggle valves...

Sherwood Botsford (z3, Alberta)

14 years ago

Related Stories

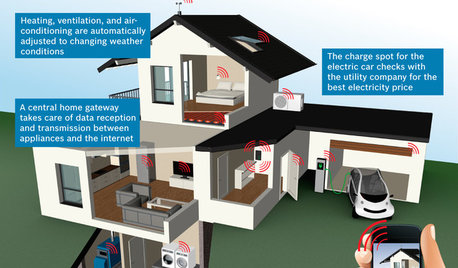

THE HARDWORKING HOMECES 2015: Inching Toward a Smarter Home

Companies are betting big on connected devices in 2015. Here’s a look at what’s to come

Full Story

UNIVERSAL DESIGN11 Ways to Age-Proof Your Bathroom

Learn how to create a safe and accessible bathroom without sacrificing style

Full Story

EARTH DAYGrow a Beautiful Garden With Ecofriendly Greywater

Reducing home water waste means lower bills and a healthier planet. Here's how to set up a greywater home irrigation system that can help

Full Story

BATHROOM DESIGNHow to Design an Accessible Shower

Make aging in place safer and easier with universal design features in the shower and bathroom

Full Story

GREAT HOME PROJECTSMake Your Own Tranquil Garden Fountain

With this DIY water feature in your yard, serenity is just a few steps away

Full Story

BATHROOM DESIGNHow to Choose Tile for a Steam Shower

In steamy quarters, tile needs to stand up to all that water and vapor in style. Here's how to get it right the first time

Full Story

HOME TECHMeet the New Super Toilets

With features you never knew you needed, these toilets may make it hard to go back to standard commodes

Full Story

BATHROOM DESIGN9 Surprising Considerations for a Bathroom Remodel

Don't even pick up a paint chip before you take these bathroom remodel aspects into account

Full Story

TRADITIONAL ARCHITECTUREHow to Research Your Home's History

Learn what your house looked like in a previous life to make updates that fit — or just for fun

Full Story

PRODUCT PICKSGuest Picks: Put a Cork in It

Buoyant, fire-resistant cork is popping up everywhere these days. Check it out on furnishings, finishes, accessories and more

Full Story

lehua49

Sherwood Botsford (z3, Alberta)Original Author

Related Professionals

Allen Landscape Architects & Landscape Designers · West Milford Landscape Architects & Landscape Designers · Manhattan Beach Landscape Architects & Landscape Designers · Summit Landscape Architects & Landscape Designers · Gainesville Landscape Contractors · Lakeland Landscape Contractors · College Park Landscape Contractors · Edwardsville Landscape Contractors · Kahului Landscape Contractors · Pikesville Landscape Contractors · Rancho Santa Margarita Landscape Contractors · New Carrollton Landscape Contractors · Northlake Landscape Contractors · Imperial Beach Solar Energy Systems · Teaneck Solar Energy Systemslehua49

Sherwood Botsford (z3, Alberta)Original Author

lehua49

Sherwood Botsford (z3, Alberta)Original Author

lehua49

Sherwood Botsford (z3, Alberta)Original Author

lehua49