Review of irrigation control valves?

Sherwood Botsford (z3, Alberta)

12 years ago

Related Stories

GARDENING GUIDESHow to Install a Drip Irrigation System

Save time and water with a drip watering system in your vegetable garden — a little patience now will pay off later

Full Story

GREEN BUILDINGHow to Harvest Rainwater for Your Garden

Conserve a vital resource and save money by collecting stormwater for irrigation in a barrel or tank

Full Story

EARTH DAYGrow a Beautiful Garden With Ecofriendly Greywater

Reducing home water waste means lower bills and a healthier planet. Here's how to set up a greywater home irrigation system that can help

Full Story

SAVING WATER6 Reasons Why You Should Save Your Rainwater Now

Collect and store during the rainy season so you’ll have water ready for irrigation when you need it

Full Story

CONTRACTOR TIPSBuilding Permits: What to Know About Green Building and Energy Codes

In Part 4 of our series examining the residential permit process, we review typical green building and energy code requirements

Full Story

REMODELING GUIDES8 Remodeling Costs That Might Surprise You

Plan for these potential budget busters to keep a remodeling tab from escalating out of control

Full Story

SAVING WATER11 Ways to Save Water at Home

Whether you live in a drought-stricken area or just want to help preserve a precious resource, here are things you can do to use less water

Full Story

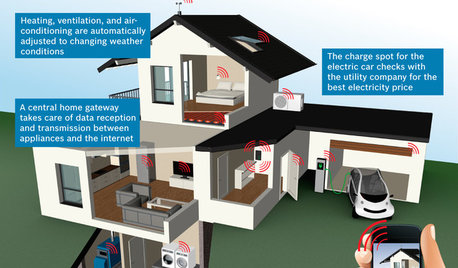

THE HARDWORKING HOMECES 2015: Inching Toward a Smarter Home

Companies are betting big on connected devices in 2015. Here’s a look at what’s to come

Full Story

SAVING WATERXeriscape Gardens: How to Get a Beautiful Landscape With Less Water

Conserve water and make gardening much easier with the xeriscape approach’s 7 principles

Full Story

GREEN BUILDINGWater Sense for Big Savings

Keep dollars in your pocket and preserve a precious resource with these easy DIY strategies

Full StoryMore Discussions

lehua49

Sherwood Botsford (z3, Alberta)Original Author

Related Professionals

Fillmore Landscape Architects & Landscape Designers · Berwyn Landscape Contractors · Canton Landscape Contractors · Concord Landscape Contractors · Fairfield Landscape Contractors · Hollywood Landscape Contractors · Lewisville Landscape Contractors · Mastic Beach Landscape Contractors · Norwalk Landscape Contractors · Nutley Landscape Contractors · Sugar Hill Landscape Contractors · Twin Falls Landscape Contractors · Vacaville Landscape Contractors · West Orange Landscape Contractors · Whitney Solar Energy Systemsmike1059

lehua49